B.U.M.E.S

BOSTON UNIVERSITY MANUFACTURING EXPERT SYSTEM

Goal: Increase efficiency, utilization, and throughput of the ADML for the manufacturing of the Organizer

Hybrid Manufacturing Approach

Automated Manufacturing Lab (ADML)

BUMES integrated three variables together to manufacture CordGanizer

VARIABLES

“Rosie” “Edie” “Mary”

ur5 Robot Arms

CNC Mills

Conveyor belt

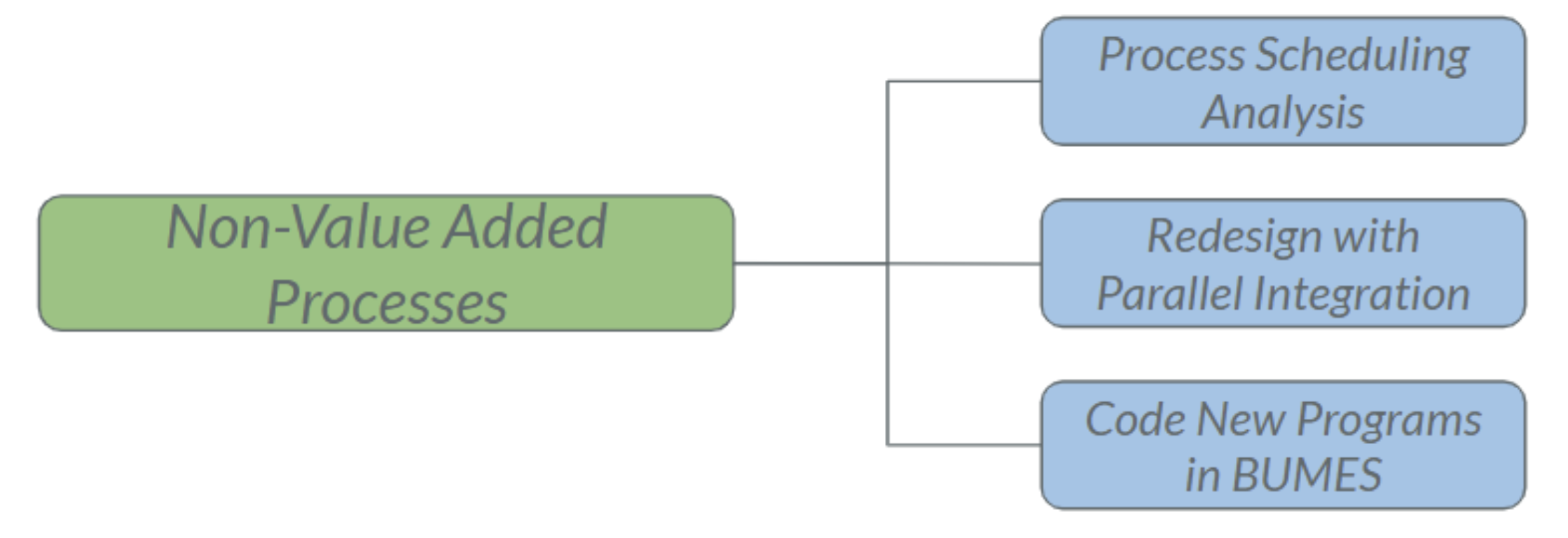

Optimizing Non-Value Added Processes

Process Description

Optimizing Value Added Processes

Ur5 Robots

Inventory

CNC Mills

Conveyor Belt

BUMES software

Variables

Optimized Waypoints and arm movements with reduced times

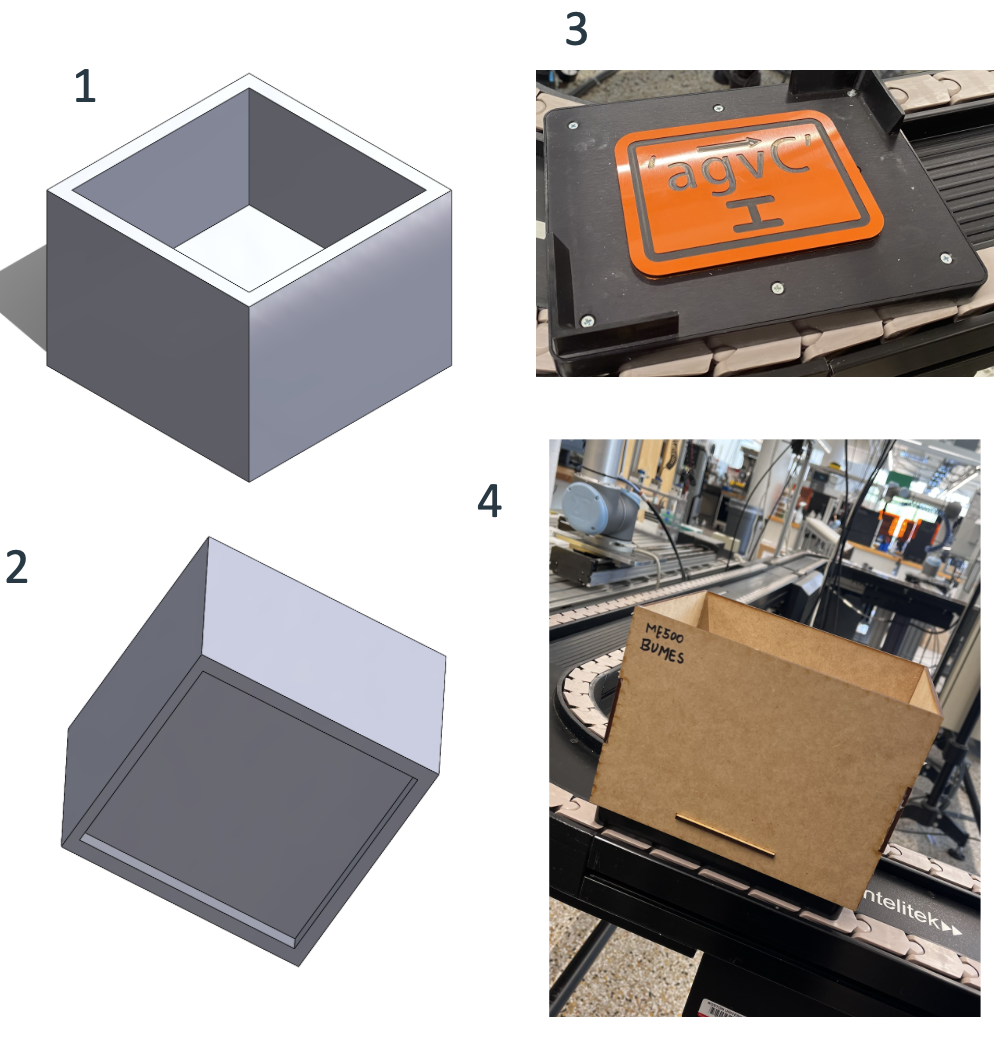

CNC Mill completes Body and Lid Operations

Assembly is finished inside the mill and the completed part gets loaded into the basket

GibbsCAM Milling Optimization

Ur5 Operations

Ur5 robot Edie is responsible for picking/placement operations of Body + Lid of the CordGanizer

Square Lid Operation

Square Body Operation

CoordGanizer Placement into Inventory